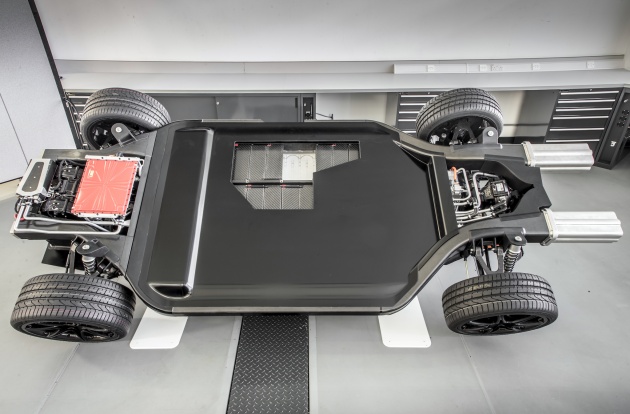

Williams Advanced Engineering has revealed details of the FW-EVX, a lightweight electric vehicle platform that will be displayed at JEC World 2018 in Paris. The platform was first previewed at last year’s Low Carbon Vehicle Event, and draws upon the company’s expertise in Formula One and Formula E.

According to the company, the FW-EVX is readily scalable for C-, C-D- and D-segment vehicles, and boasts innovations relating to cooling systems, lightweight components and the assembly process.

In terms of cooling, the bonded aluminium and carbon composite centre module of the FW-EVX platform includes chassis side rails that provide cooling air for the battery pack, as well as being controlled crush zones to absorb impact in a crash.

The air is collected through ducts at the front of the vehicle, which is then channelled to internal radiators before exiting at the rear via an aerodynamic diffuser. This approach not only reduces aerodynamic drag normally associated with heat exchangers, but the exiting air can be used to help create downforce.

To further increase the efficiency of the cooling system, the battery modules feature an aluminium base plate that is attached to the thermally conductive vehicle floor that acts like a heat sink. “The high level of integration creates a virtuous circle where each improvement in weight and functionality leads to additional benefits,” said Paul McNamara, technical director at Williams Advanced Engineering.

On the mention of the battery, Williams developed a new method of creating an engineered hinge embedded in a single composite preform, which allows 3D structures to be created from 2D materials then folded when required.

The company calls it the 223 process, and it is used in the construction of the low and slim battery module, which consists of ultra-stiff honeycomb of interlocking composite boxes containing the battery cells.

Each box is manufactured in sheet form, before being folded and bonded to create the required shape. This production method creates a tough ex-skeleton that contributes to structural performance, and in turn, crash protection as well.

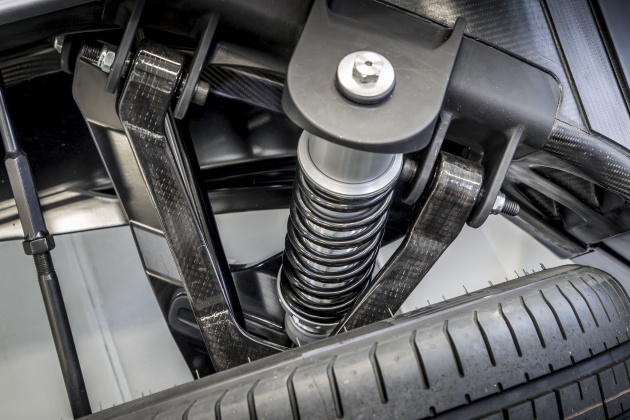

The FW-EVX platform also uses weight-saving composite materials to reduce heft, like the suspension wishbones – press-formed from 80% recycled carbon composite that are 40% lighter than aluminium forgings while being comparable in cost to produce. The wishbones are produced using a highly automated, near zero waste process called RACETRAK, which has a cycle time of just 90 seconds.

In a typical C-segment application, the platform weighs just 955 kg, and that includes the all-round wishbone suspension, up to four electric motors (one for each wheel), 4WD transmission, steering and an 80 kWh lithium-ion battery pack weighing 350 kg.

The company is targeting two sets of customers for the FW-EVX – carmakers looking for a next-generation EV platform that brings the benefits of highly integrated design, and those seeking specific areas of technology for their own platforms.

“An electric vehicle constructed on the FW-EVX platform can be lighter, safer, greener and much more cost-effective. This potential performance would be greater even than a design adapted from a conventional vehicle or one assembled from individual state-of-the-art systems from technology suppliers,” said McNamara.

“By designing the key systems as an integral part of an aluminium/composite vehicle chassis, we have greatly reduced many of the compromises that arise when the individual elements of an EV powertrain are sourced separately, forcing the vehicle architecture to be created around stand-alone packages,” he added.