The sparkling green hydrogen economy of the future is a long way off, but meanwhile scientists at the Weizmann Institute of Science in Israel are hot on the trail of a hydrogen-based energy storage system that could resolve at least two significant obstacles: safety and cost.

Before we dive in the usual caveat applies: hydrogen fuel cell electric vehicles are lagging far behind their battery-powered cousins in terms of mass market appeal, but hydrogen has innumerable other uses as a fuel and industrial chemical. The global race is on to produce, store, and transport renewable H2 at scale.

Mother Nature’s Energy Storage System

The next time you walk past your house plant, give it a thumbs-up for its ability to effortlessly store energy in the form of hydrogen without setting itself on fire or blowing itself up.

Here’s an explainer from our friends over at Science Daily:

…In biological cells, finely adjusted chemical compounds bind and release hydrogen to build up the chemical compounds needed by the cells. All these biological processes are catalyzed by enzymes.

The tricky part comes in where scientists try to replicate 700 million years of evolution within a few years of lab work, and translate that into an artificial system that can be scaled up to massive proportions.

Here Comes The Hydrogen Economy…

One interesting breakthrough occurred back in 2013 a research team at Virginia Tech developed an enzyme-based formula for extracting H2 from biomass, using the common plant sugar xylose as a springboard.

Our friends over at Wikipedia note that xylose comes in several forms. Here’s one that explains why researchers have been eyeballing plants for H2 production and energy storage: HOCH2(CH(OH))3CHO.

On the storage end, researchers have been tinkering around with liquid organic H2 carrier (LOHC) systems inspired by plant-based chemistry since at least the 1980s.

In 2016, the American Chemical Society journal Accounts of Chemical Researchpublished a review of LOHC literature in 2016 titled, “Liquid Organic Hydrogen Carriers (LOHCs): Toward a Hydrogen-free Hydrogen Economy.“

The authors provide a handy one-liner on the chemistry behind LOHC energy storage systems:

LOHC systems are composed of pairs of hydrogen-lean and hydrogen-rich organic compounds that store hydrogen by repeated catalytic hydrogenation and dehydrogenation cycles.

…Wait For It…

Got all that? They also explain the allure of LOHC systems:

Recent scientific and technological progress in handling hydrogen in chemically bound form as liquid organic hydrogen carrier (LOHC) supports the technological vision that a future hydrogen economy may work without handling large amounts of elemental hydrogen.

The main point of the LOHC exercise is to provide for the massive energy storage capacity required in a global economy that leans heavily on wind and solar power. Long-term storage and transportability also come into play.

The authors describe how a liquid hydrogen energy storage system could fit right into existing liquid fuel infrastructure without much, if any, tweaking. They also factor in the public’s familiarity with liquid fuels, which could help accelerate mass-market adoption of H2 stored in liquid form.

Earlier this year, a paper published through the Royal Society of Chemistry also weighed in with this observation on the feasibility of large scale intercontinental H2 transportation in LOHC systems:

“…Overall, LOHCs can provide technologically efficient and economic promisingstorage and transport within a sustainable hydrogen economy.”

…Wait For It…

The new H2 research from the Weizmann Institute fits neatly into the area of high volume storage and transportation. The authors make the case that the H2 economy will not come into full flower until something is done about “low energy density by volume, safety issues, cost of compression in high-pressure tanks or cryogenically, and weight of the containers.”

Ouch!

The researchers lay claim to a “novel liquid organic hydrogen carrier (LOHC) system, with a high theoretical hydrogen capacity, based on the unpresented hydrogenation of ethylene urea to ethylenediamine and methanol, and its reverse dehydrogenative coupling.”

Got all that? Basically, it’s a rechargeable H2 battery:

This system is rechargeable,as the H2-rich compounds could be regenerated by hydrogenation of the resulting dehydrogenation mixture. Both directions for hydrogen loading and unloading were achieved using the same catalyst, under relatively mild conditions.

The key to the system is a catalyst based on ruthenium, a silvery transition metal.

You can get more details from the journal Angewandte Chemie International, a publication of the German Chemical Society, under the title, “Chemical Hydrogen Storage System: Reversible liquid organic hydrogen carrier system made of simple organic chemicals.“

The research team deployed their catalyst on H2 gas and the compound ethylene urea, which produced a compound of ethylenediamine and methanol. Using the same catalyst, they also reversed the procedure to produce pure H2 and ethylene urea.

Don’t hold your breath for that H2 battery just yet. So far the team’s LOHC system has achieved a theoretical capacity of 6.52% by weight. That’s awfully good for an LOHC system, but translating theory into a mass-marketable contraption is going to take some more elbow grease.

It seems that some further exploration in the area of sustainable chemistry is also in order. Though the compounds explored by the Weizmann team are “abundant, cheap, easily handled, and not very hazardous,” next steps for the team include finding a more efficient catalyst to cut down on energy inputs.

For even more details check out the full H2 research paper under the title, “A Reversible Liquid Organic Hydrogen Carrier System Based on Methanol-Ethylenediamine and Ethylene Urea.“

…The Hydrogen Economy Is Here, Says US DOE

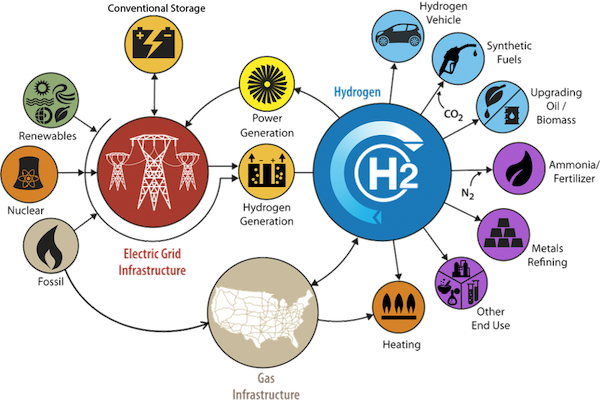

So, here’s where it gets interesting. Some energy observers have raised the idea that H2 energy storage could have the unintended effect of making coal and nuclear power more economical. During periods of low demand, electricity from these power plants could be used to produce H2 from water.

The same would go for natural gas power plants. For that matter, renewable H2 from water (or biomass, or wherever) also needs to scale up bigly if it wants to replace the primary source for hydrogen today, which is natural gas.

On the bright side, the falling cost of wind and solar seems to be shutting the door on the fossil and nuclear options. Energy Secretary Rick Perry is already floating the idea that concentrating solar power plants could sub in for baseload fossil and nuclear power plants, so there’s that.

Meanwhile Perry’s agency is forging ahead with its H2@Scale initiative. Last week DOE announced a new $31 million round of funding with a focus on producing renewable H2 from water.