Batteries in electric vehicles can fail quickly, sometimes catching fire without much warning. Sandia National Laboratories is working to detect these failures early and provide sufficient warning time to vehicle occupants.

While electric vehicles have systems to detect performance issues with lithium-ion batteries, these systems are not focused on imminent safety concerns.

“The nature of battery fires can vary widely, depending on the failure mode. Some batteries self-heat for hours, while others are abrupt and aggressive,” said Alex Bates, a member of Sandia’s battery safety group. “The battery starts heating uncontrollably, ultimately resulting in a fire.”

Current measurements in battery management systems capture temperature and voltage, but these are lagging indicators of safety issues. This means a warning may not appear until it’s too late—when the battery is about to catch fire or is already on fire.

“We’re focused on extending the warning time,” said Loraine Torres-Castro, Sandia’s battery safety lead. “Our aim is for the diagnostic system to provide an early warning, allowing time to park safely and exit the vehicle.” She added that the ultimate goal is to integrate this warning system into the car’s dashboard.

The BATLab

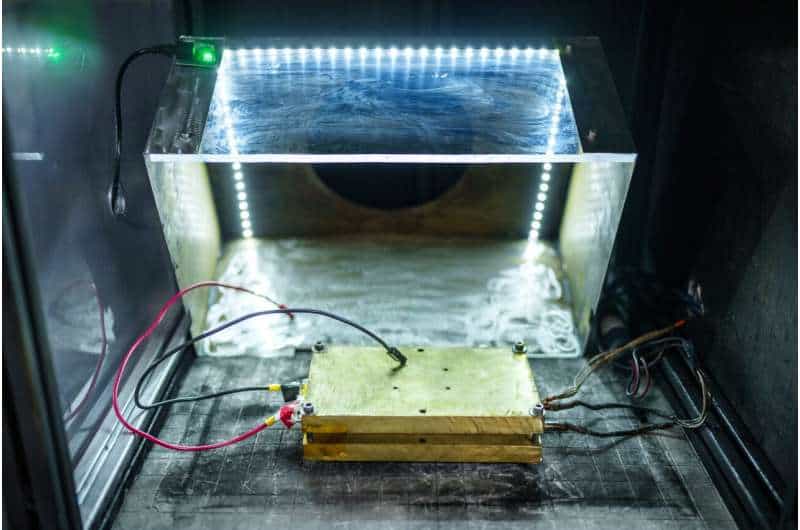

To achieve this, Torres-Castro and her team have been testing commercial off-the-shelf diagnostics on single cells and battery packs at the Battery Abuse Testing Laboratory.

“Our objective is to benchmark commercially available solutions for different failures that exhibit varying responses and require tailored diagnostics,” Torres-Castro said. “One size does not fit all. We seek to identify specific tools that can provide early warnings for particular failure conditions, battery chemistries and cell engineering.”

Sandia is uniquely positioned to do this work, not only because of the BATLab.

“We have broad expertise on our team,” Torres-Castro said. “We understand material science, electrochemistry, engineering and, most importantly, how and why batteries fail.”

A paper published earlier this year in the Journal of the Electrochemical Society describing Sandia’s research has gained significant attention.

“It’s important work. Industry is interested in this space. It’s still wide open,” Bates said. “This manuscript has largely started the conversation, or at least pushed it to the forefront of battery safety for electric vehicles.”

The paper highlighted techniques used to detect failure markers and has implications beyond batteries for electric vehicles.

“We’re working with an organization in South Korea to evaluate the potential use of this technique in grid energy storage systems. We’re talking about large batteries,” Torres-Castro explained.

Next steps

Torres-Castro and Bates agree there’s a lot more work to do on electric vehicle battery failure detection.

“The next phase is understanding the limitations and applying machine learning algorithms to datasets,” Bates said. “We need other methods to examine the signal and ensure that it’s fast, accurate and not a false positive.”

Another focus area is advancing sensor technology to the point that the sensors issue more than warnings.

“These tools can also activate mitigation measures. For instance, upon receiving a warning the system could trigger the thermal management system of the battery to start cooling it down,” Torres-Castro said.

As a next step, Sandia will have battery packs from electric vehicles in the lab. The cells will be disassembled and tested at different scales to check the limitations of the current diagnostics on the market.

“It’s very exciting to be at the forefront of practical battery safety, where our work will extend beyond the lab,” Torres-Castro said.

Bates added, “We’re always excited about the science.”