Lithium-ion batteries have been a revelation in energy technology. They’re in everything—from electric vehicles to your cell phones to those high-tech suitcases you can’t check on an airplane. They are also super efficient at storing energy, allowing a lot of power to be packed into a fairly small battery.

But, unfortunately for everyone, lithium-ion batteries have a few drawbacks, and depending on who you ask, they’re big ones. The batteries are made with materials that can only be gathered through environmentally damaging means, they degrade over time and begin to store less and less power, and under the right conditions, they can fully catch fire.

Remember that batch of Galaxy Note 7s that spontaneously exploded a few years back? Faulty lithium-ion batteries.

Obviously, even though lithium-ion batteries have a lot of benefits, downsides that big open up space for innovation in the energy-storage space. And a team from the Vienna University of Technology in Austria is trying to solve a few of those issues with their new invention: the oxygen-ion battery.

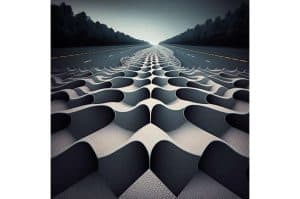

According to the scientists, oxygen-ion batteries work much the same way as lithium-ion batteries do. They cause ions—atoms that acquire an electrical charge by gaining or losing electrons—to jump back and forth between two surfaces and create and electrical current. In the case of these new batteries, those surfaces are made of ceramic.

“We have had a lot of experience with ceramic materials that can be used for fuel cells for quite some time,” Alexander Schmid, one of the developers of the oxygen-ion battery, said in a press release. “That gave us the idea of investigating whether such materials might also be suitable for making a battery.”

And as it turns out, they were. Ceramic oxygen-ion batteries aren’t made from any materials that damage the planet in their extraction, they are completely flame-resistant (so no surprise fire), and they don’t degrade. According to the team, an oxygen-ion battery is basically infinitely rechargeable without ever getting worse at holding that charge.

That long lifespan is the thing researchers are most excited about, because it gives the battery huge implications in the field of green energy. When you collect energy from, say, a wind turbine or a solar panel, that energy has to be stored somewhere before it can be delivered to the devices that will put it to use. So, to make that system work, you need a battery that can be recharged almost constantly. With lithium-ion batteries, they eventually break down and won’t be able to serve their purpose anymore. That’s the not the case with the oxygen-ion version.

But these new energy storage containers aren’t a fix-all. The batteries can’t hold the same energy density as lithium-ion batteries (making them less efficient), and they get hot. Really hot, as in 200 to 400 degrees Celsius hot. So, while they would have huge benefits on the scale of a wind farm, they have way more drawbacks on the scale of a cell phone.

Still, the potential is there. At large scales, “the lower energy density and increased operating temperature do not play a decisive role,” says Schmid in a press release. “But the strengths of our battery would be particularly important there: the long service life, the possibility of producing large quantities of these materials without rare elements, and the fact that there is no fire hazard with these batteries.”

And as we know how much we all rely on electricity every day, it certainly seems worth further investigation.