The team at Zap&Go has developed a new energy storage technology that combines the rapid charging of superconductors and, with the help of carbon nanotubes and some tech from the University of Oxford, turns them into a battery that has the potential to revolutionize the growing world of energy storage.

CleanTechnica spoke with Zap&Go CEO Stephen Voller about its new battery tech and how he believes it has the potential to transform not just electric vehicles, but the entire world of energy storage that underpins the broader clean energy revolution.

What is the solution?

Zap&Go’s new Carbon-Ion or C-Ion battery is the result of years of research at the prestigious University of Oxford that is currently in its 3rd generation, according to Voller. “It’s a supercapacitor that performs like a battery,” Voller said. “The conventional supercapacitor is great at charging really fast but doesn’t hold onto its energy for very long.”

The breakthrough came when Zap&Go used carbon nanotube technology to combine the fast charging benefits of supercapacitors with the energy storage characteristics of a battery. The result is an extremely fast-charging battery that is built without the need for any rare earth metals or toxic chemicals like the cobalt that underpins many of today’s lithium-ion battery chemistries.

In Zap&Go’s Carbon-Ion battery, “the principle material is carbon, which is readily available in many forms,” Voller said. For now, Zap&Go is using carbon sourced from coconut shells, but Voller noted that he expected the source to change over time as demand grows.

In addition to ultra-fast charging, Zap&Go’s new Carbon-Ion battery is poised to change the energy storage game because of its impressive lifespan expectations. “We last a long time,” Voller said. “It would be a 30-year useful life or 30-year warranty,” which is a far cry from the 10- to 15-year lifespans expected from today’s lithium-ion batteries.

As if ultra-fast charging and 30-year life expectancies weren’t enough, Voller dropped another bombshell: “You don’t get any degradation in that time, or at least none that we’ve been able to measure.” That is made possible by the supercapacitors that underpin Zap&Go’s solution. “In a battery, it is an electrochemical reaction,” Voller said. As you use the battery, the chemistry wears out over time, resulting in a lower capacity over the life of the battery. “With a Carbon-Ion cell, it’s an electrostatic reaction. It’s like static electricity.” That translates to energy storage that won’t wear out over time and that can charge and discharge instantly.

That’s a trifecta of game-changing specs that, if Zap&Go can deliver them at a competitive cost, would change the world. Batteries that could charge up and discharge much more rapidly than today’s batteries would blow current battery chemistries out of the water in performance. Doing so over a 30-year (or greater) lifespan with zero degradation means that they can be amortized over a much longer period, resulting in lower total cost of ownerships and better payouts.

Electrifying Vehicles

Today, Zap&Go is in production of its third generation units that operate at 3.4 volts, according to Voller. “These cells are designed for grid storage, not electric vehicles,” so don’t get too excited about seeing them in electric vehicles anytime soon. EV batteries are definitely in the longer term outlook for Zap&Go, and the technological glide path is clear. “We are developing our generation 4, which is operating at 4 volts.”

Voller noted that on the current trajectory, it will take two more generations for their batteries to get into vehicles. “It will be our gen 5 and gen 6 that will go on a vehicle,” he said. In practical terms, that should be around 2025 when they first make it to the electric vehicle market.

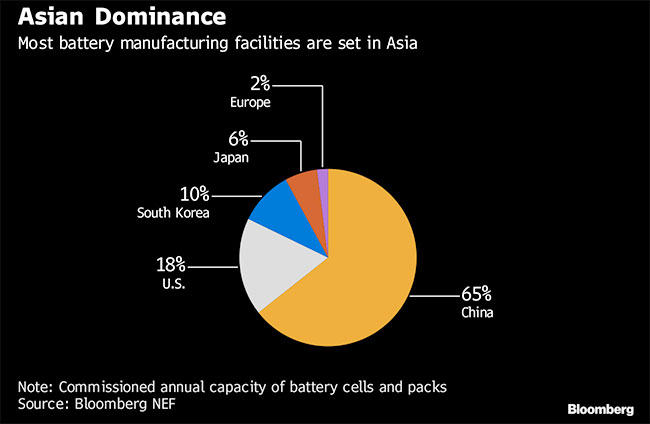

The great news with these new cells is that they can all be made in the same factories and the same production lines that existing lithium ion batteries are produced on. “We’re making our generation 3 cells today in China at an existing lithium ion plant.” That translates to a lower cost transition as battery makers will not have to build new production lines, purchase new equipment or risk as much to start building the new cells.

Current demand for their cells is for stationary energy storage applications, like at EV charging stations. Plug-in vehicles pull a significant amount of power down in a short time which results in demand charges that penalize electricity consumers for the amount of power they pull. Installing stationary energy storage in conjunction with charging stations allows operators to absorb cheaper power over a longer period of time that can then be doled out to vehicles when it’s time to charge. That translates to a reduction in demand chargers and a lower cost of operation for station owners.

Zap&Go has only started churning its cells out in serious production volumes in the last 12 months and now sees a healthy pipeline of demand ahead as cities, states and countries look to zero emission vehicles to solve their urban pollution issues. These legislative changes have brought new business to their doorstep and brought new interest in their battery technology, Voller said.