Lithium hopeful Liontown Resources was hoping to raise up to A$7.9-million through a share placement to fast-track exploration and development activities at its Australian lithium projects.

The ASX-listed company on Thursday said that it would undertake a one-for-five non-renounceable pro-rata rights issue to raise an initial A$4.5-million, as well as a placement to institutional and professional investors, priced at 2c a share, to raise a further A$3-million.

Subject to shareholder approvals, the company would raise a further A$350 000 through a share placement to directors.

“The response to the capital raising from both new and professional investors and our major shareholders has been extremely encouraging, with the demand for the placement well exceeding funds sought to be raised,” said Liontown MD David Richards.

Liontown will issue the first 150-million new ordinary shares to eligible professional and institutional investors under Tranche 1 of the placement, with Tranche 2, consisting of 17.5-million shares, subject to shareholder approval.

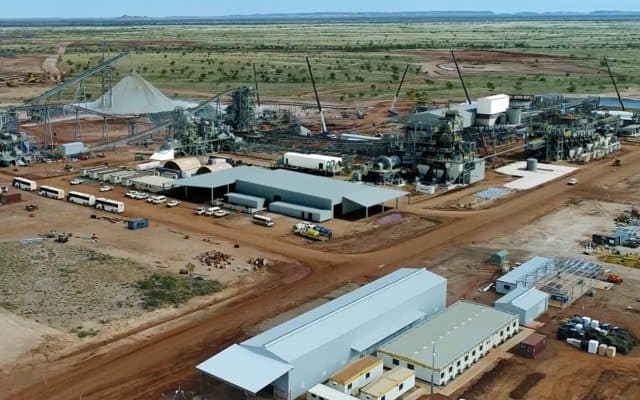

He said that the funding would enable the company to rapidly advance the project development activities at its Kathleen Valley operation, following the recent completion of a scoping study, which confirmed the potential to establish a commercially robust mining operation.

“Resource expansion drilling is already in progress and we are confident that we can significantly extend the mine life from the current nine years outlined in the study. Important metallurgical test work is also ongoing to optimise grade and recoveries as a prelude to further feasibility studies this year.”

At Buldania, Liontown is working on definition drilling at the Anna prospect, as a precursor to a maiden mineral resource estimate. The company will also test a number of newly discovered spodumene-bearing pegmatities, which are some 5 km northwest of Anna.

“2019 will be an exciting and busy year for Liontown where shareholders can expect strong news flow as we work both to unlock value and de-risk our assets, positioning the company to be a significant new supplier of lithium raw materials to the rapidly expanding lithium-ion battery industry.”