Light duty electric vehicles with battery packs of up to 100kWh use three to four times the amount of copper of gasoline and diesel-powered equivalents: 80-85kg in the high-voltage batteries and motors of EVs compared to 20-25kg for low voltage wires in internal combustion engined cars.

For plug-in hybrids the total is around 60kg of copper while full electric trucks like the upcoming Rivian and Hummer models with battery packs of more than 180kWh can be double that.

A little less than half of the copper in the average EV is found in the battery primarily as foil for the anode material.

In a note BMO Capital Markets points out that due to its thinness, conformity and light weight, electrodeposited (ED) copper foil is deemed the most suitable for battery applications.

The investment bank says this has led to a surge in newly announced ED copper foil manufacturing capacity, with around 1 million tonnes of annual output announced in 2021 and due to be commissioned over the next 5-7 years.

ED foil manufacturing mostly utilises high-grade scrap and so competition for copper scrap is set to intensify, while the impact on refined copper may be more muted, says BMO.

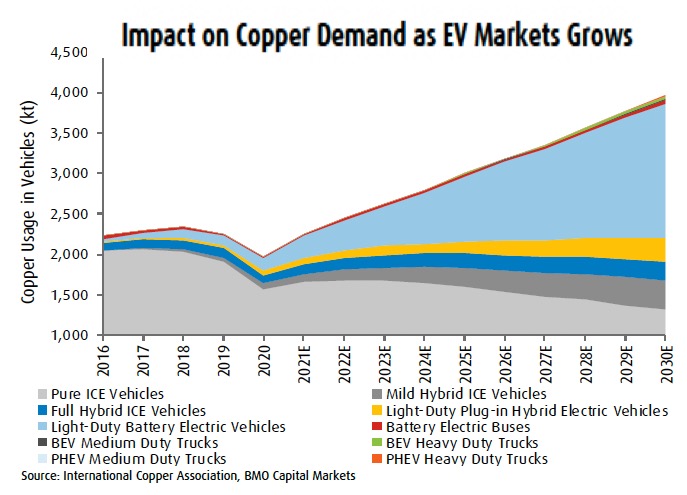

Wood Mackenzie, an energy and metals researcher, expects end-use copper demand from passenger EVs (including hybrids) to jump to around 2.9 million tonnes over the next decade from roughly 600,000 tonnes in 2021.

That compares to annual mined production of some 21 million tonnes and total copper scrap use of nearly 6 million tonnes.

Copper prices were trending down on Wednesday trading around $4.40 a pound or $9,700 a tonne in New York, shrugging off surprisingly strong growth figures from the US and China shifting back into economic stimulus mode.